Description

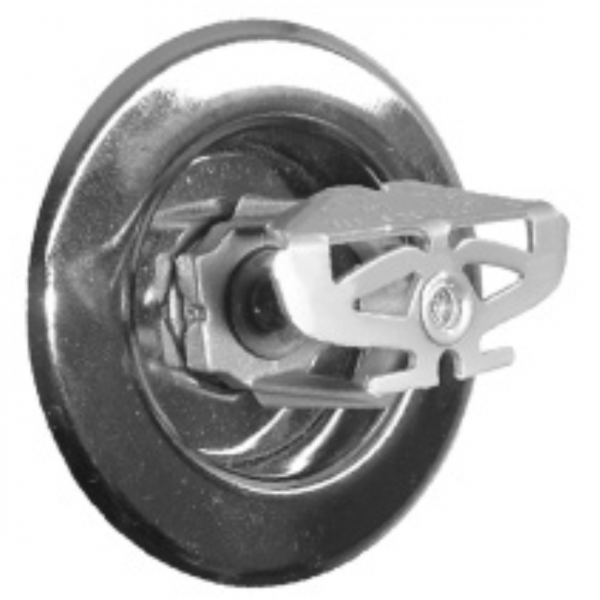

The TYCO Series TY-B, 5.6 K-factor, Horizontal and Vertical Sidewall Sprinklers described in this technical data sheet are standard response, standard coverage decorative 5 mm glass bulb type spray sprinklers designed for use in light and ordinary hazard, commercial occupancies such as banks, hotels, and shopping malls.

They are designed for installation along a wall or the side of a beam and just beneath a smooth ceiling. Sidewall sprinklers are commonly used instead of pendent or upright sprinklers due to aesthetics or building construction con- siderations, where piping across the ceiling is not desirable.

The recessed version of the Series TY-B Horizontal Sidewall Sprinkler is intend- ed for use in areas with a nished wall. It uses a two-piece Style 10 Recessed Escutcheon. The Recessed Escutcheon provides 1/2 inch (12,7 mm) of recessed adjustment or up to 3/4 inch (19,1 mm) of total adjustment from the ush side- wall position. The adjustment provided by the Recessed Escutcheon reduces the accuracy to which the xed pipe nipples to the sprinklers must be cut.

Corrosion-resistant coatings, where applicable, are utilized to extend the life of copper alloy sprinklers beyond that which would otherwise be obtained when exposed to corrosive atmospheres. Although corrosion re- sistant coated sprinklers have passed the standard corrosion tests of the applicable approval agencies, the test- ing is not representative of all possible corrosive atmospheres. Consequently, it is recommended that the end user be consulted with respect to the suit- ability of these coatings for any given corrosive environment. The effects of ambient temperature, concentration of chemicals, and gas/chemical velocity, should be considered, as a minimum, along with the corrosive nature of the chemical to which the sprinklers will be exposed.